Key Takeaways:

- Understand the importance of electrical safety in commercial environments.

- Learn the essential safety measures to implement in commercial buildings.

- Discover the significance of regular electrical inspections and maintenance.

- Explore the role of employee training in maintaining a safe electrical system.

The Importance of Electrical Safety in Commercial Buildings

Electrical safety is critical to maintaining a secure and functional commercial environment. Neglecting safety measures can result in severe consequences, including electrical fires, equipment damage, and even human injury. According to the National Fire Protection Association (NFPA), an estimated 15% of fires in commercial properties are caused by electrical failures or malfunctions. Such incidents risk human lives and result in significant financial losses and disruptions to business operations. Therefore, businesses must prioritize electrical safety protocols to safeguard their premises and personnel.

To achieve this goal, many companies seek the expertise of professionals, such as a land development engineer, who can provide comprehensive assessments and recommendations. These experts are adept at identifying potential risks and offering solutions that enhance electrical safety in commercial settings.

Regular Electrical Inspections and Maintenance

Regular inspections and maintenance are key to sustaining electrical safety in commercial buildings. It’s advisable to schedule periodic inspections by qualified professionals who can detect and correct any flaws in the electrical system. These experts are trained to identify issues that may not be immediately apparent, such as wear and tear on wiring, corrosion, or other forms of degradation. Additionally, maintaining a record of all inspections and repairs can help track the condition of electrical components and plan future maintenance effectively. By being proactive, little problems can be stopped before they become bigger ones, protecting the electrical system’s dependability and safety.

Scheduling Periodic Inspections

Depending on the complexity and age of the electrical system, inspections should be done at least once a year, if not more often. These inspections should include testing safety equipment like smoke detectors and alarms, assessing circuit load capacities and checking wiring integrity. Frequent inspections reduce the chance of electrical fires and equipment failures by assisting in the early detection of possible problems.

Maintaining Inspection Records

Keeping detailed records of inspections and repairs can be invaluable. These records help assess the electrical system’s health over time and provide crucial information for planning timely maintenance or upgrades. Additionally, documentation can be useful for complying with safety regulations and standards, ensuring that the business meets all requirements for electrical safety.

Addressing Common Electrical Issues

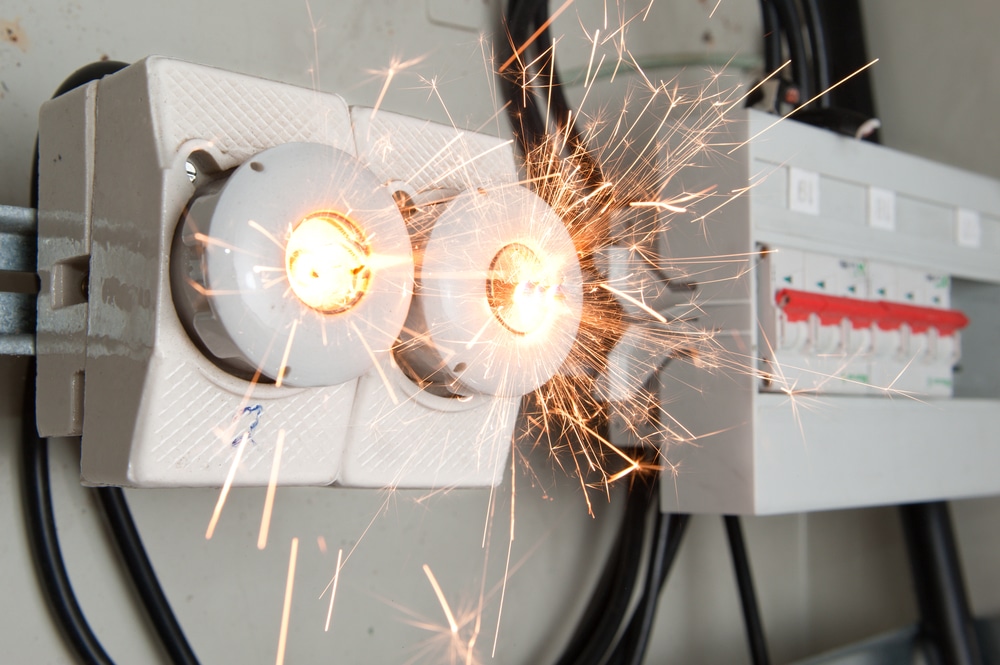

Common electrical issues in commercial buildings include overloaded circuits, exposed wiring, and outdated equipment. Addressing these issues promptly is vital to prevent disruptions and hazards. Overloaded circuits can lead to frequent tripping of breakers, and exposed wiring poses a danger of electric shock or fire. For instance, replacing old wiring and upgrading to energy-efficient lighting and appliances can significantly reduce the risk of electrical malfunctions and improve overall safety. By proactively addressing these common issues, businesses can maintain a safer and more efficient electrical system.

Overloaded Circuits

An overloaded circuit can cause breakers to trip frequently and lead to overheating, which poses a significant fire hazard. Businesses should ensure that circuits are appropriately rated for their load and avoid plugging too many devices into one outlet. Regular assessments of circuit loads and adjustments as needed can prevent overloads and enhance safety.

Exposed Wiring

Exposed wiring is dangerous as it can easily contact people or flammable materials. Regular inspections should include checks for exposed or damaged wires and repairing them promptly. Electrical accident risk can be considerably decreased by ensuring all wiring is adequately insulated and shielded.

Leveraging Technology for Electrical Safety

Technology is crucial in enhancing electrical safety. Modern advancements, such as smart electrical panels and monitoring systems, allow for real-time tracking of electrical usage and early detection of anomalies. Leveraging these technologies can help businesses avoid potential issues and maintain a safer electrical system. Embracing technological solutions can lead to more efficient management and a greater understanding of electrical systems.

Smart Electrical Panels

Bright panels offer real-time monitoring and control over electrical systems, allowing facility managers to detect irregularities and optimize power distribution efficiently. These panels can provide alerts and notifications when potential issues arise, enabling prompt action to prevent problems from escalating.

Monitoring Systems

Modern monitoring systems can notify staff members of possible issues before they become more serious, allowing for prompt action and lowering the possibility of mishaps or equipment failure. Monitoring systems can measure temperature, current flow, voltage levels, and other factors to provide a comprehensive picture of the electrical system’s state.

Creating an Electrical Safety Culture

Creating a culture of electrical safety within the workplace involves continuous education and vigilance. Encouraging employees to report electrical issues immediately and conducting regular safety drills can reinforce the importance of electrical safety. A proactive approach ensures that safety remains a top priority and minimizes the risk of accidents. Fostering a safety-first mindset among employees can lead to a more compliant and aware workforce.

Encouraging Reporting

Encouraging workers to report electrical problems in a comfortable environment can expedite the treatment of minor issues and keep bigger hazards at bay. Employees can efficiently voice issues by implementing a reporting system that is easy to understand and accessible.

Regular Safety Drills

Regular safety drills ensure that all employees are prepared to respond appropriately in an electrical emergency, enhancing workplace safety. Drills should be designed to simulate real-life scenarios and provide practical experience in handling emergencies.

Conclusion

Upholding electrical safety in business buildings is a continuous duty that calls for attention to detail and preemptive action. Businesses may dramatically lower the risk of electrical dangers by making frequent inspections a priority, putting in place crucial safety procedures, and providing employee training.